Screen printing

What is screen printing?

Screen printing, also known as silk screening, is the most popular way to print custom t-shirts.

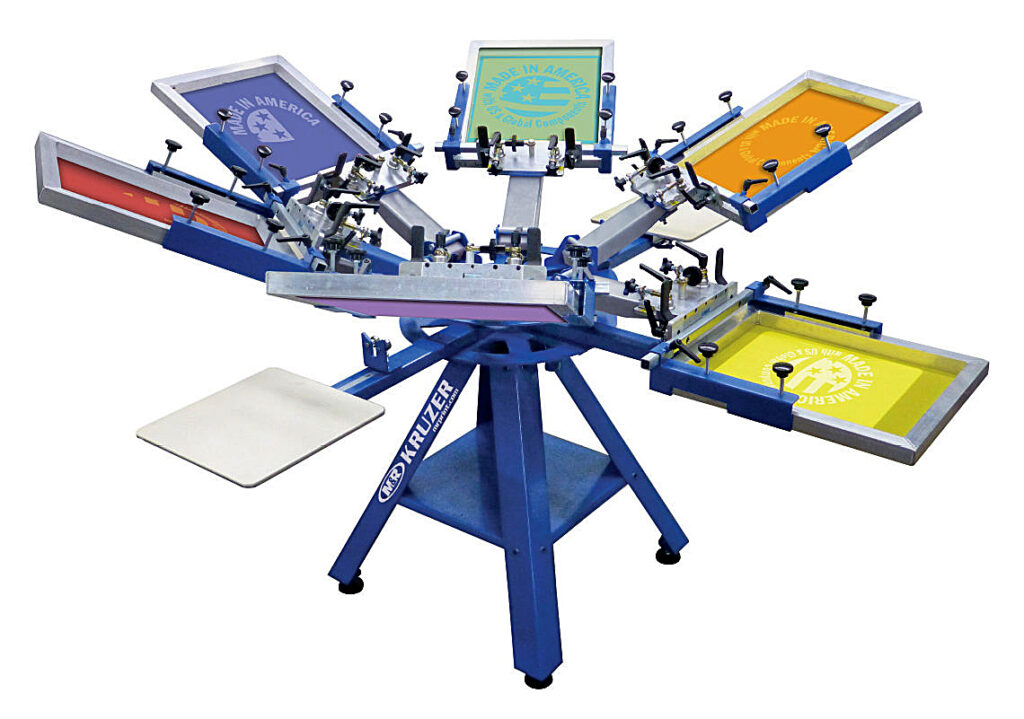

We create one screen per ink color, set up the screens on one of our precision presses, and print your design in quantities of 24 to 24,000 and beyond.

Screen printing isn’t just for t-shirt printing – it works well on hoodies, polo shirts, tote bags, and more!

We prepare a separate screen (a bit like a large stencil created on a mesh) for each color in your design.

The shirt is sandwiched between the screen and the pallet, and ink for the first color is pressed through the screen onto the shirt with a squeegee.

The machine revolves to the next station, and the shirt gets pressed with the second color, and so on.

Will it work for my design?

Screen printing can accommodate many design needs in terms of complexity, detail, and colors.

Pricing

Screen printing is a mass-production process, so to determine if your project is cost-effective for screen printing we recommend following this rule of thumb:

One-color artwork = order at least 24 shirts

Two-color artwork = order at least 36 shirts

Three-color artwork = order at least 48 shirts

Screen preparation and machine set are labor intensive, so it can be expensive to screen print small quantities of shirts (especially for art with many colors). Often vinyl is best for those orders. However, once it’s set up, the machine is efficient, and screen printing is usually the lowest-cost method for printing large quantities.

A screen print is vibrant, with a fairly soft hand feel.

Are there special inks for screen printing?

Standard plastisol ink is vibrant and long-lasting, and works great for 95% of projects.

- Water-based / discharge screen printing

- Puff screen printing

- High density screen printing

- Reflective inks

How do I order?

Pricing is based on several factors, including: